Table of Contents

Inroduction

Welcome to the Living Computer Museum's Wiki Page!

Below you will find information on the Computers available over the Internet from the LCM through ssh.

Most systems have GUEST access, but if you are interested in long term access you can request an account.

To request a login, visit https://livingcomputers.org/Online-Resources/Online-Systems.aspx

Note that you may need to disable your ad blocker to be able to submit this form.

HOW-TO Connect

Once you have a login, you may connect to the host using:

ssh host@tty.livingcomputers.org -or- ssh menu@tty.livingcomputers.org

Where host is the name of the host you wish to connect to (refer to the list below). This will connect you across a telnet bridge to the host. You will then be prompted to log in with the account you have been granted. The second example will log you into the MENU system which acts as a springboard to all available remote systems.

You can also access the MENU system in the browser at https://ssh.livingcomputers.org:4443

Mainframes

DECsystem-10 KA 1050

Model: KA-10 1050

OS: TOPS-10 v6.03a (TOPS-10 Survival Guide)

Host: ka175

DECsystem-10 KI 1090

Model: KI-10 1090

OS: TOPS-10 v6.03A (TOPS-10 Survival Guide)

Host: ki587

DECSYSTEM-20 KL 2065

Model: KL-10 2065

OS: TOPS-10 v7.04 (TOPS-10 Survival Guide)

Host: dec-10

DECsystem-10 KL 1095

Model: KL-10 1095

OS: WAITS

Host: waits

DECSYSTEM-2020

CDC

Xerox XDS

Model: Sigma 9

OS: (CP-V Survival Guide)

Host: sigma9

XKL

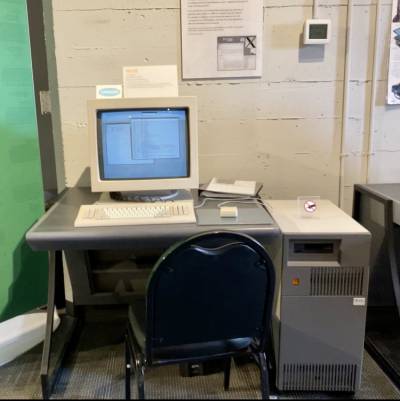

Minicomputers

AT&T

Model: 3B2 1000-70

OS: UNIX System V3.2.3

Host: lcm3b2

SUN

Model: SUN 3/160

OS: SunOS Release 4.1.1

Host: three

DEC

Model: PDP-11, decdatasystem 11/570

OS: UNIX V7

Host: pdp1170

Model: PDP-8/e

OS: TSS/8

Host: tss8

Model: VAX-7000/640

OS: OpenVMS V7.3

Host: vax7000

Model: VAX-11/730

OS: 4.3BSD

Host: vax730

Model: VAX-11/780-5

OS: Research UNIX 8th Edition

Host: vax785

from left to right: the vax7000, vax730 and vax785

Model: AlphaServer AS-1000

OS: TRU64 v5.0

Host: truly

Model: PDP-11/84

OS: 2.11 BSD

Host: snake

Hewlett Packard

Model: K266

OS: HP/UX 10.20

Host: oz

IBM 4300 Series

Model: 4361

OS: VM/SP Release 5

Connect: Use a 3270 terminal emulator to connect to host tty.livingcomputers.org port 24.

Note: As of September 2019, the IBM 4361 is online and remotely accessible, but due to space limitations in the computer room it is not currently on public display.

A VM/CMS Survival Guide exists to guide the first time user of the IBM mainframe environment.

Interdata

Model: 7/32

OS: UNIX 6th Edition

Simulated Systems

TYMCOM-X

Honeywell

Model: 6180

OS: Multics MR12.6e

Host: multics

Simulator: DPS8M

DEC

Model: PDP-6 sn 4

OS: ITS 1648

Host: its

Programming Languages

Machines and Operating Systems

a list of remotely accessible systems at LCM+L

| Hostname | Operating System | Machine Hardware |

|---|---|---|

| multics | Multics MR12.6f | Honeywell 6180 |

| toad-2 | TOPS-20 7(110131)-1 | XKL TOAD-1 |

| sigma9 | CP-V C00 | XDS Sigma-9 |

| cdc6500 | NOS 1.3 | CDC-6500 |

| lc | ITS ver 1648 | PDP-6 sn 4 |

| ka175 | TOPS-10 6.03a | KA10 1050 |

| kl2065 | TOPS-10 7.04 | KL10 2065 |

| rosencrantz | OpenVMS 7.3 | VAX 7000-640 |

| bitzone | NetBSD BBS | AMD64 |

| misspiggy | UNIX v7 | decdatasystem 570 |

| zippy | UNIX v8 | VAX-11/780-5 |

| lcm3b2 | UNIX SVR3.2.3 | AT&T 3B2/1000-70 |

| guildenstern | 4.3BSD | VAX-11/730 |

| snake | 2.11BSD | PDP-11/84 |

| oz | HP/UX | HP9000/K266 |

| truly | Tru64 | Alpha AS1000 |

| macready | ULTRIX | PDP-11/84 |

The BiTz0ne BBS

The BiTz0ne BBS is an ASCII retro-styled Electronic Bulletin Board System.

ASCII Text Gaming

A list of interesting text based games (not definitive)

| Game | Year | Genre | Systems available on |

|---|---|---|---|

| adventure | 1975,1976 | Adventure | XKL TOAD-2, decdatasystem 570, IBM 4361 |

| hack | 1983 | Adventure | VAX-11/780-5 |

| HAUNT | 1979 | Adventure | XKL TOAD-2 |

| MANHUNT | 1980s | Puzzle | XKL TOAD-2 |

| lander | 1989 | Action | AT&T 3B2 1000-70 |

| mazewar | 1988 | Shooter | AT&T 3B2 1000-70 |

| mdg | 1990 | Adventure | AT&T 3B2 1000-70 |

| MONSTER | 1970s | Turn based, Adventure | CDC-6500 |

| nethack | 1985,1989 | Adventure | AT&T 3B2 1000-70 |

| Oregon Trail | 1971,1978 | Adventure | Xerox XDS Sigma 9, XKL TOAD-2, CDC-6500 |

| sokoban | 1989 | Puzzle | AT&T 3B2 1000-70 |

| tesseract | 1983,1988 | Adventure | AT&T 3B2 1000-70 |

| tetris | 1989 | Puzzle | AT&T 3B2 1000-70 |

| rogue | 1980 | Adventure | VAX-11/780-5 |

| VTTREK | 1979 | Multiplayer TREK | XKL TOAD-2 |

| wanderer | 1988 | Puzzle | AT&T 3B2 1000-70 |

| WUMPUS | 1979 | Turn based, shooter | XKL TOAD-2 |

| ZORK | 1978 | Adventure | XKL TOAD-2 |